For decades, technology has been considered as a main driving force behind economic development but nowadays there are concerns about all this economic growth at the expense of environmental sustainability. When designing a machine, we need to ensure that technical aspects are met without adversely impacting the environment. Electrical industry is also playing its part in sustainable development by introducing “green alternatives” which not only comply with environmental constraints but also have better properties to offer. Mineral oil has long been used worldwide for transformer insulation and cooling because of good electrical and physical properties, low cost, and ease of accessibility. However, due to non-biodegradability, chemical toxicity, fire susceptibility of mineral oil and ever-increasing push towards eco-friendly alternatives, ester oil (as a replacement for mineral oil) was introduced in late 90’s. Ester oil being biodegradable, non-toxic to living things and having better fire resistive properties is more appealing to end users who have been slowly shifting towards the adoption of ester oil based distribution transformers. This article will analyze and compare technical properties, environmental aspect, and life cycle cost of ester and mineral oil transformers.

Performance Comparisons – Ester vs Mineral Oil Transformers

Ester oil, natural or synthetic in origin, is derived from 100% renewable vegetable oils or inorganic feedstock. Commercial use of ester oil in distribution transformers began in 1996 when it was initially designed as a green alternative to polychlorinated biphenyles (PCBs) and High Molecular Weight Hydrocarbons. Research has been going on for more than two decades to enhance safety, environmental impact, and performance capabilities of ester oil; this has helped in establishing its position as a superior alternative to mineral oil.

Transformer Fire Protection

Transformer fires are predominantly mineral oil fires which can occur at any time, but the threat increases with the overloading and ageing of transformers. Most major utilities anticipate more than one fire incident per year in present operating conditions. At their worst, transformer fires have caused loss of life and significant damage to the surrounding environment. From fire safety perspective, ester oil is almost two times safer than mineral oil. With over two million installations of ester oil distribution transformers worldwide, zero fire incidents have been reported, reducing the need for fire mitigation measures including deluge systems and clearance spaces. In absolute terms, total cost of damage resulting from ester oil based distribution transformer fire is approximately 20% less than from mineral oil transformer fire considering the repair costs and damage to the surroundings. Temperature of mineral oil rises with transformer loading, leading to thermal degradation of insulation system, posing a potent fire hazard. As per IEC standard 61100, ester oil is classified as ‘K fire hazard class’ dielectric insulating fluid. Consequently, even if a distribution transformer catches fire, ester oil having a fire point ≥ 300°C and low calorific value would get extinguished soon.

Eco Sustainability

Unlike mineral oil, ester oil is biodegradable when exposed to environment as per OECD 301 (Organization for Economic Co-operation and Development). In case of a transformer failure, natural habitat in the surroundings would not be contaminated by the spill out because of its non-toxic nature. Due to environment friendly nature of ester oil, spill mitigation and cleanup procedures are comparatively less costly. Also, ester oil combustion emits fewer toxic greenhouses gases compared to mineral oil fire which produces carbon, nitrogen, and sulfur oxides as a byproduct.

Enhanced Properties of Ester Oil

Temperature is one of the major factors limiting the lifetime and loading capability of transformers. Ester oil features higher thermal conductivity compared to mineral oil which can be used to better regulate average winding rise of (AWR) of the transformer. Using ester oil as a dielectric media, insulation system of a distribution transformer can be run at 20°C warmer conditions, thus increasing the loading capability of transformer for the same life expectancy. Furthermore, the transformer with ester oil can operate better in areas with high ambient temperature.

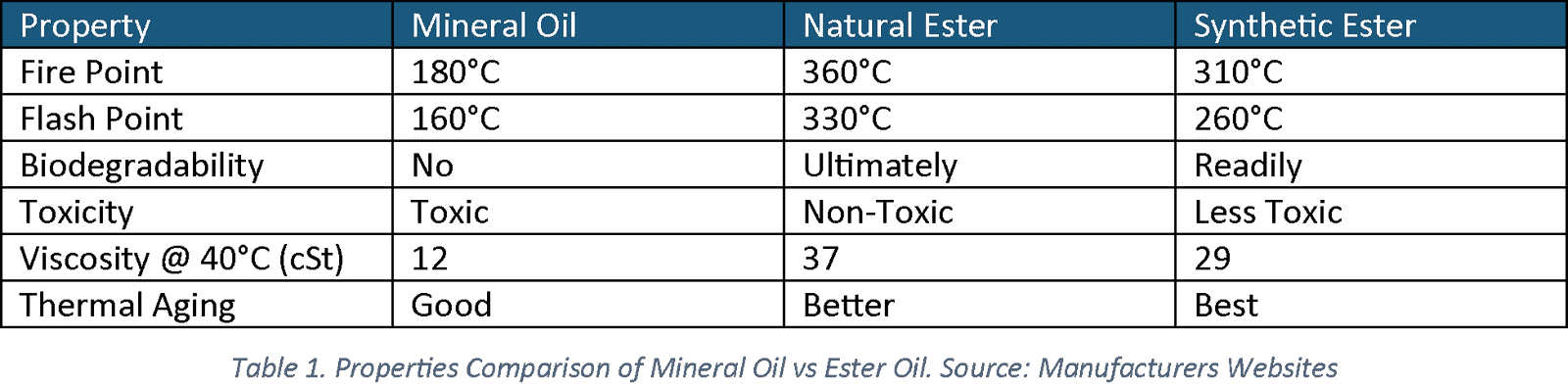

The oxidation stability of the transformer fluid is also one of the most important parameters for transformer maintenance and it is a key concern for end users. Oxidation of mineral oil produces sludge precipitates, while ester oil is much more resistant to oxidative degradation. Table 1 summarizes the enhanced properties of ester oil against mineral oil.

Cost Benefit Analysis

The initial purchase price of “green transformers” can be up to 20% higher than conventional mineral oil transformers. Therefore, both tangible (increased asset lifetime) and non-tangible (environment friendly & inherent safety) factors need to be taken into consideration while performing cost benefit analysis of using ester oil in distribution transformers. As per a conservative estimate by a distribution utility in United States, ester oil extends lifespan of a distribution transformer by almost 33%, compensating for increased initial capital cost compared to mineral oil transformers. As the cellulose insulation degrades at elevated temperature, moisture content of insulation increases leading to decrease in dielectric strength. Ester oil can extend insulation lifetime almost 6-8 times by continuously drying out the moisture content from cellulose paper at 10 times faster rate than mineral oil. Cellulose insulation failure is one of the top three reasons for a transformer failure.

Also, footprint of distribution transformers can be significantly reduced by using ester oil, allowing transformers to be rated and operated at higher temperature as recognized by IEEE C57.154. As ester oil distribution transformers can be continuously overloaded (10% at least) for the same lifetime, small nameplate rating transformers with overloading capabilities can be installed in lightly loaded areas to meet peak hours demand. This allows initial asset investment and total operating costs to be lower while still reaping the benefits of life extension and better thermal capability.

Retrofilling

Due to urbanization, industrialization and electrification, global demand for energy is on the rise, burdening the distribution network of a country. With the penetration of renewables into the decades old grid infrastructure, many mineral oil transformers are being overloaded to meet operating conditions, accelerating the ageing of paper insulation, potentially reaching the end of life. Retrofilling (replacing existing mineral oil transformers with ester oil) these transformers is a cost-effective way to slow down thermal aging rate of insulation, enabling overload capability of transformer and increasing system reliability with almost same efficiency. Figure 1 illustrates the percentage split between new installations and retrofills of ester oil distribution transformers globally for 2018.

Ester Oil Transformers – An Alternative to Dry Type Transformers

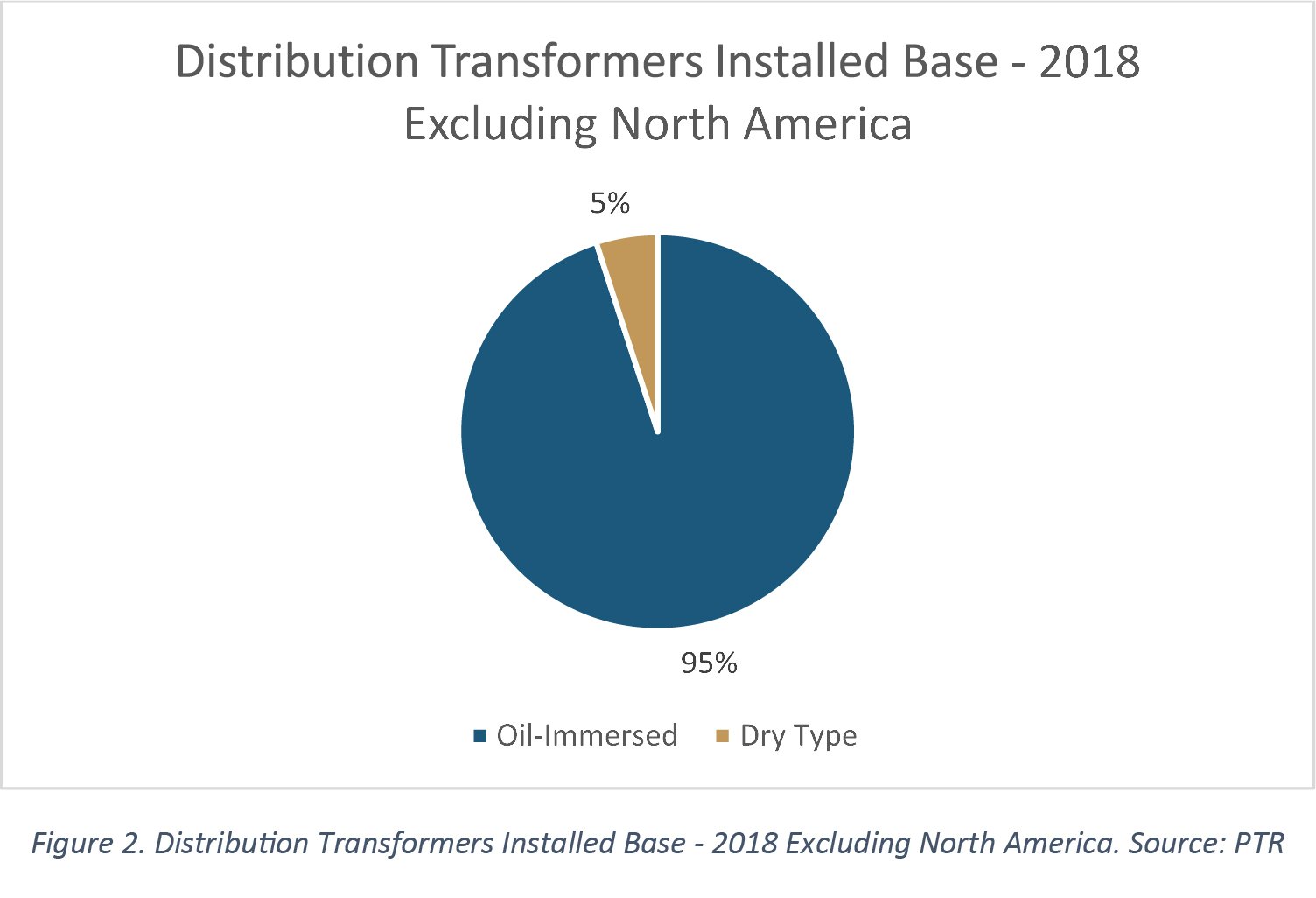

Ester oil transformers fall into the general category of oil-immersed distribution transformers, which covers almost 95% of the installed base as compared to dry type transformers. However, dry type transformers are being used in many industries and utilities to avoid potential fire hazards posed by mineral oil transformers, particularly in navy applications and nuclear power plants etc. According to PTR’s analysis, some of the dry type transformers in these applications will shift towards ester oil distribution transformers due to enhanced fire resistance properties of ester oil.

Ester Oil Transformer Market Outlook

Ester oil distribution transformers featuring advantages like reduced fire risk, improved environmental footprint, optimized transformer performance and increased life expectancy easily offset the initial capital cost of new installations. In addition, retrofilling the installed base of distribution transformers can significantly increase system reliability, delay transformer replacements based on age and increase overloading capability beyond the nameplate rating. Recently, there has been exponential rise in adoption of ester oil distribution transformers especially in Americas and Europe with major utilities (TransnetBW, PG&E, EWEB, SMUD etc.) and manufacturers shifting their focus towards these “green transformers”. OEMs setting up production facilities of ester oil in MEA and APAC region also anticipate increased deployment of ester oil transformers regionally. APAC and Europe region would experience significant penetration of renewables into their grid infrastructure by 2025 as depicted in Figure 3. These markets can prove to be a winning opportunity for OEMs offering ester oil distribution transformers as they are able to sustain longer operation of peak load and are also compatible with variable duty cycle of renewables (wind & solar).