Solliance announces the demonstration of an industrially-applicable roll-to-roll process for the production of solar cells, achieving a record 12.6% conversion efficiency on cell level.

Impression: For the amount of announcements about Perovskite solar cells (PSC), it is welcome news to hear about more commercial-oriented developments happening as well. The announcement specifically states the R2R process was developed for both the electron transport and the perovskite layers. A R2R process is a good step towards addressing the manufacturing element of Perovskites in general as most of the other players are still producing one off units in the lab. Continuous throughput will also directly lead to the answer about costs, a claim that many have made of Perovskites being much cheaper than silicon crystalline technologies.

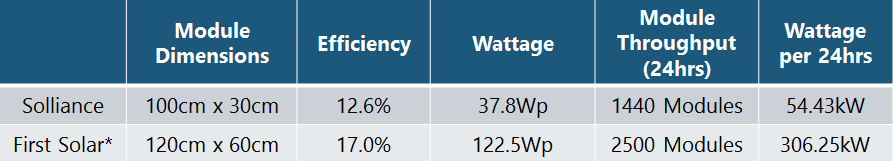

In order to come to a more quantified understanding of what this announcement by Solliance means, PTR decided to benchmark this announcement against First Solar’s established module production process. From the announcement, the Solliance R2R PSC line produced a 500cm strip of 30cm wide material in a minute (discounting the additional, off-line finishing step). At 12.6% efficiency, we are looking at 189WP per module, assuming they create 100cm modules. To put it in perspective, First Solar produces 2,500 60cm*120cm modules per line, per day. This roughly translates into one module every 35 seconds per line and the modules are on 17% efficient (122.5WP).

It goes without saying that the PSC technology has some ways to go; however, the fact we can start to measure outputs relative to other commercially viable technology, means it is getting closer to that target. PTR looks forward to benchmarking PSC on a kilowatt hour (kWh) basis once stabilities improve and will continue to keep a close eye on Perovskite improvements as part of its Solar Technology Service.

*assumptions for First Solar are the line throughputs stated in their 2016 annual report and their Series 4 V3 modules rel=”nofollow”.

April 5 Update:

PTR has received further information from Dyesol since our original impression about some of the aspects behind this announcement. It is confirmed that the absorbing material is of an organo-lead halide perovskite. Dyesol believes that considerable up-speeding of the production rate can be achieved with optimization of the process parameters despite challenges of retaining conditions that produce the required perovskite crystal morphology. It is also anticipated that in a manufacturing scenario, all production steps would be closely coupled, including encapsulation.

Link to press release: here