Contact: Hassan Zaheer, Power Technology Research, Germany

hassan.zaheer@ptr.inc

+49-89-12250950

Press Release Date: 17th July 2020

- According to PTR’s analysis on Distribution Transformers, a greater shift from Mineral Oil Transformers to Ester Oil Distribution Transformers will be observed as Major Utilities and Industries shift their focus to green transformers.

- Recently, there has been exponential rise in adoption of ester oil in distribution transformers especially in Americas and Europe with major utilities (TransnetBW, PG&E, EWEB, SMUD etc.) and manufacturers procuring these transformers.

- “Ester oil distribution transformers market to experience a hike as major utilities and industries shift their focus to “Green Transformers.” – Predicts Azhar Fayyaz at Power Technology Research

Munich, Germany – 17th July 2020

Mineral oil has long been used worldwide for transformer insulation and cooling because of good electrical and physical properties, low cost, and ease of accessibility. However, due to non-biodegradability, chemical toxicity, fire susceptibility of mineral oil and ever-increasing push towards eco-friendly alternatives, ester oil being biodegradable, non-toxic to living things and having better fire resistive properties is more appealing to end users who have been slowly shifting towards the adoption of ester oil based distribution transformers.

“Ester oil transformers fall into the general category of oil-immersed distribution transformers, which cover almost 95% of the installed base as compared to dry type transformers. According to PTR’s analysis, some of the dry type transformers markets will shift towards ester oil distribution transformers due to enhanced fire resistance properties of ester oil.” says Azhar Fayyaz.

Transformer fires are predominantly mineral oil fires which can occur at any time, but the threat increases with the overloading and ageing of transformers. Most major utilities anticipate more than one fire incident per year in present operating conditions. At their worst, transformer fires have caused loss of life and significant damage to the surrounding environment.

“From fire safety perspective, ester oil is almost two times safer than mineral oil.” – Azhar Fayyaz.

With over two million installations of ester oil distribution transformers worldwide, zero fire incidents have been reported, reducing the need for fire mitigation measures including deluge systems and clearance spaces.

“In absolute terms, total cost of damage resulting from ester oil distribution transformer fire is approximately 20% less than from mineral oil transformer. The initial purchase price of ester oil-based transformers can be up to 20% higher than conventional mineral oil transformers.” – Azhar Fayyaz.

Therefore, both tangible (increased asset lifetime) and non-tangible (environment friendly & inherent safety) factors need to be taken into consideration while performing cost benefit analysis of using ester oil in distribution transformers. Cellulose insulation failure is one of the top three reasons for a transformer failure. As the cellulose insulation degrades at elevated temperature, moisture content of insulation increases leading to decrease in dielectric strength. Ester oil can extend insulation lifetime almost 6-8 times by continuously drying out the moisture content from cellulose paper at 10 times faster rate than mineral oil. Footprint of distribution transformers can be significantly reduced by using ester oil, allowing transformers to be rated and operated at higher temperature as recognized by IEEE C57.154. As ester oil distribution transformers can be continuously overloaded (10% at least) for the same lifetime, small nameplate rating transformers with overloading capabilities can be installed in lightly loaded areas to meet peak hours demand. This allows initial asset investment and total operating costs to be lower while still reaping the benefits of life extension and better thermal capability.

Due to urbanization, industrialization and electrification, global demand for energy is on the rise, burdening the distribution network of a country. With the penetration of renewables into the decades old grid infrastructure, many mineral oil transformers are being overloaded to meet operating conditions, accelerating the ageing of paper insulation, potentially reaching the end of life. Retrofilling (replacing existing mineral oil transformers with ester oil) these transformers is a cost-effective way to slow down thermal aging rate of insulation, enabling overload capability of transformer and increasing system reliability with almost same efficiency. Figure below illustrates the percentage split between new installations and retrofills of ester oil distribution transformers globally for 2018.

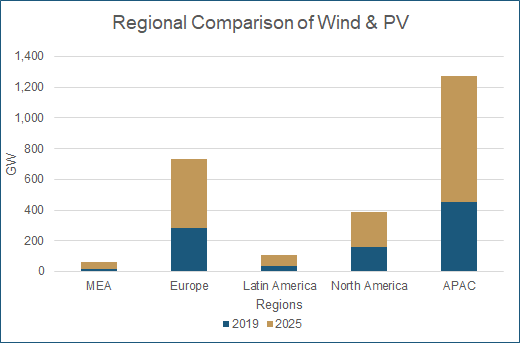

In essence, ester oil distribution transformers featuring advantages like reduced fire risk, improved environmental footprint, optimized transformer performance and increased life expectancy easily offset the initial capital cost of new installations. In addition, retrofilling the installed base of distribution transformers can significantly increase system reliability, delay transformer replacements based on age and increase overloading capability beyond the nameplate rating. Recently, there has been exponential rise in adoption of ester oil distribution transformers especially in Americas and Europe with major utilities (TransnetBW, PG&E, EWEB, SMUD etc.) and manufacturers shifting their focus towards these “green transformers”. OEMs setting up production facilities of ester oil in MEA and APAC region also anticipate increased deployment of ester oil transformers regionally. APAC and Europe region would experience significant penetration of renewables into their grid infrastructure by 2025 as depicted in Figure 3. These markets can prove to be a winning opportunity for OEMs offering ester oil distribution transformers as they are able to sustain longer operation of peak load and are also compatible with variable duty cycle of renewables (wind & solar).

—————————————-

About the Distribution Transformers Research

Power Technology Research’s Distribution transformers service covers the market of Distribution Transformers analyzing individual countries for new additions, expansions and replacement in utilities, generation plants and Industry. Distribution networks, interacting with the end-consumers of electricity are usually the most complex and least understood part of the grid. Especially with an active increase in Distributed Generation (DERs) and Electric Vehicle (EV) penetration, grid dynamics at the distribution level are more complex than ever. We start by analyzing the key utilities having the majority of the market share to understand equipment use patterns and utilize that information to model the remaining country. For industrial distribution transformers, we select key high growth industries in the country and analyze industry specific markets by country. With this approach, we are able to analyze the behaviors of the all the major buyers in the market and can identify these opportunities for you. To learn more, visit: http://ptr.inc/services/grid/distribution-transformers/

Power Technology Research provides specialized market research within Power Grid and E-Mobility industries through bespoke and syndicated research for our clients among Fortune-500, FTSE-100, DAX-30, NIKKEI 225 companies. Founded by engineers and market research professionals with decades of combined experience in global market research firms. The company was built on three pillars of excellence: Transparency, Diligence, and Digestibility. With a differentiated approach to market research, Power Technology Research can assist you in identifying, valuing, and bench-marking opportunities in a multitude of topics within these industries. To learn more, visit: https://ptr.inc/