• Around 47% of the global ammonia was produced in Asia-Pacific, Russia and Caspian region produced around 14%, North America produced 10% while Europe and Middle East produced 9% each.

• Requirement of large storage volumes despite high energy density with limited existing infrastructure is impeding the development of hydrogen economy.

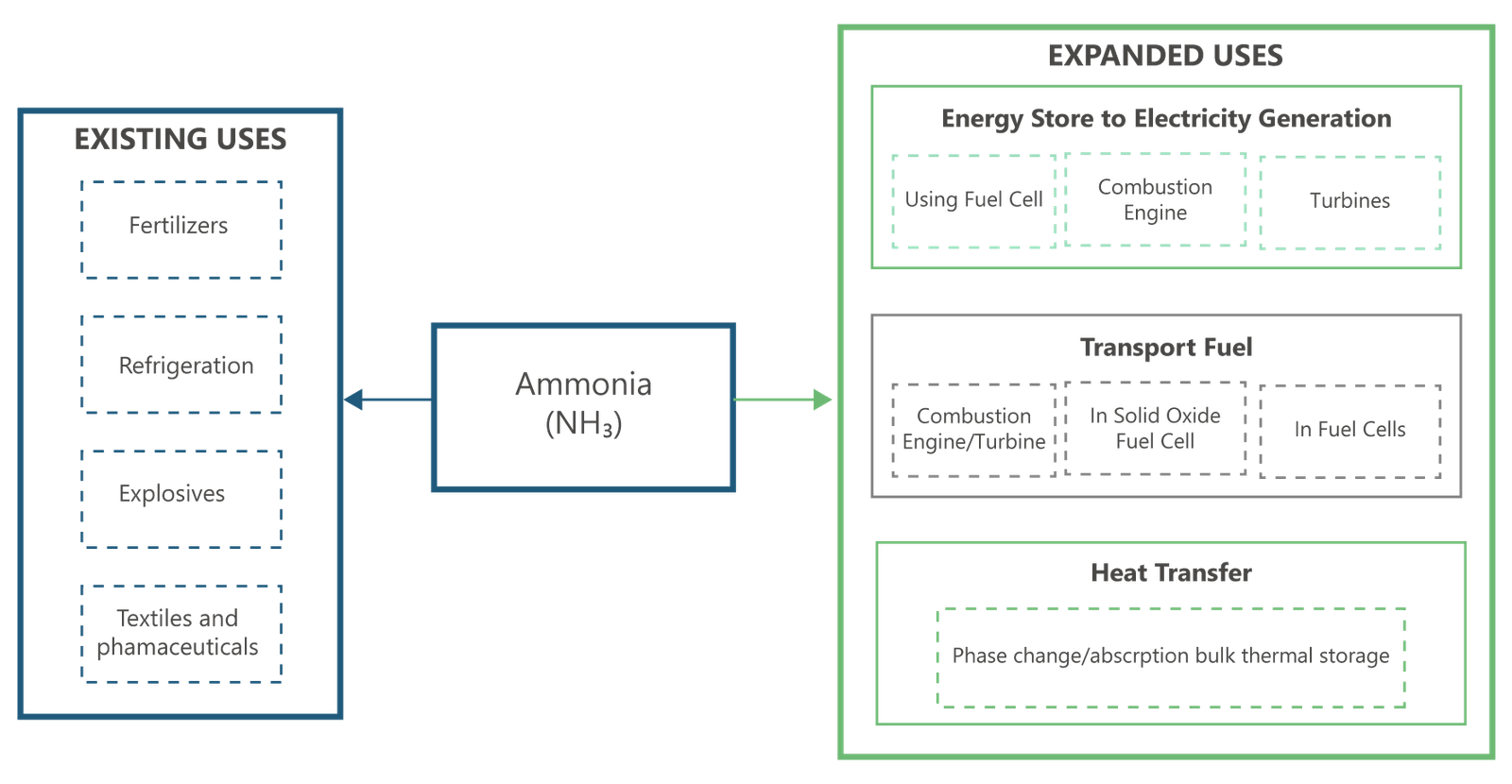

Ammonia is a primary chemical for the fertilizer industry and nearly 70% of the ammonia produced worldwide is used in the fertilizer industry whereas around 30% is utilized in several other industrial applications for instance plastics, explosives and synthetic fibers. It forms the backbone of the global agricultural system and as the world population is increasing, the ammonia production is expected to observe significance growth as well.

Currently, an overwhelming majority of the ammonia produced in the world, accounting for more than 50% of the global production, is produced in only four countries that include Russia, China, US and India. On the other hand, 99% of the ammonia is produced through coal regasification and steam methane reforming to produce hydrogen. Therefore, for green hydrogen production to grow substantially it is imperative that the production of ammonia is decarbonized.

According to Power Technology Research, China produced 30%, Russia produced 10%, US produced 9% while India 7% of the global ammonia produced in 2021.Similarly, segregation of global ammonia production by region in 2021 indicate that around 47% of the global ammonia was produced in Asia-Pacific, Russia and Caspian region produced around 14%, North America produced 10% while Europe and Middle East produced 9% each.

As far as the production process of ammonia is considered it is an energy and carbon intensive process. Countries across the globe in pursuit of their climate goals are pushing to either partially or completely decarbonize ammonia production.

Figure 1: Existing and Expanded Uses of Ammonia.

Source: Power Technology Research

Ammonia Production-Energy and Carbon Intensive Ammonia Production

As per IEA, in 2020, global ammonia production accounted for around 8.6 EJ of final energy consumption (beyond 95% of consumption was from fossil fuels) and around 450 Mt of CO2 emissions. On a commercial scale globally, ammonia is largely being produced from Haber Bosch process that involves catalytic reaction of hydrogen and nitrogen at high temperature and pressure to produce brown ammonia. Brown ammonia production is a very energy intensive process that requires around 8 MWh of energy to produce 1 ton of ammonia.

Figure 2: Major Ammonia Producing Countries in 2021.

Source: Power Technology Research

Figure 3: Global Ammonia Production by Region in 2021.

Source: Power Technology Research

Majority of the energy consumption and carbon emissions while producing ammonia take place during the production of hydrogen. In order to reduce the carbon footprint of ammonia production technologies like carbon capture can be deployed that can help produce blue ammonia. But the process will increase the consumption of natural gas which in turn increases the cost of hydrogen production.

In order to completely decarbonize ammonia production, hydrogen can be produced with the help of electrolysis of water, nitrogen can be extracted from air while the Haber Bosch process can be powered through renewable generation. Multiple green and blue ammonia projects are being planned worldwide for instance in Europe green and blue hydrogen projects with an accumulative electrolyzer power requirement of around 7000 MW is planned from 2022 onwards. Similarly, in Middle East Saudi Arabia, UAE and Oman are leading the market with a planned accumulative electrolyzer power requirement of around 5100 MW. On the other hand, Chile, India and Australia have a planned accumulative electrolyzer power requirement of 5649 MW, 1500 MW and 24737 MW respectively. It is significant to note that power requirement of the electrolyzer indicates the hydrogen production capacity which in turn is used as an input for ammonia production.

Figure 4: Planned Ammonia (Green and Blue) Projects from 2022 Onwards.

Source: Power Technology Research

Looking Ahead

Requirement of large storage volumes despite high energy density with limited existing infrastructure is impeding the development of hydrogen economy. In order to remove this bottleneck Ammonia is now being considered as a potential carrier for hydrogen as it has high volumetric energy density than hydrogen and is significantly easier to transport and store. Fifty percent more hydrogen by volume is contained in ammonia as compared to liquid hydrogen. Deployment of ammonia as a hydrogen carrier has a serious potential but the industry will have to cater the issues concerning efficiency and safety associated with the use of ammonia first.

Hydrogen Service Overview

The research presented in this article is from PTR's Hydrogen service. For information about this service please submit a request shown below.

Contact Sales:

Europe

+49-89-12250950

Americas

+1 408-604-0522

Japan

+81-80-7808-1378

GCC/Rest of APAC

+971-58-1602441

More about our:

Hydrogen Market Research

Recent Insights

Sustainability Across Sectors: Highlights from GreenTech Festival 2024

Recently, I had the privilege to attend and present at the Greentech Festival, an excellent event in the realm of sustainability. This influential...

US and EU Strategies in Smart Buildings

Download Service Overview The EU and USA aim to decarbonize their building sectors to meet emission reduction targets. Initiatives like the Home...

Setting Sail with Hydrogen: Challenges, Opportunities, Policies, and Industry Initiatives

The maritime industry faces intense pressure to reduce greenhouse gas (GHG) emissions, curb environmental impact, and sail towards a greener future....